Austenitic Gray Iron in ASTM A436

Austenitic Gray Iron in ASTM A436

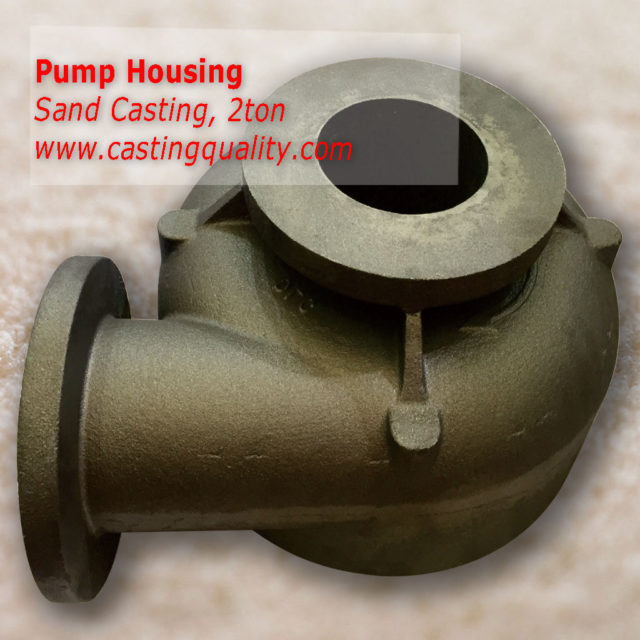

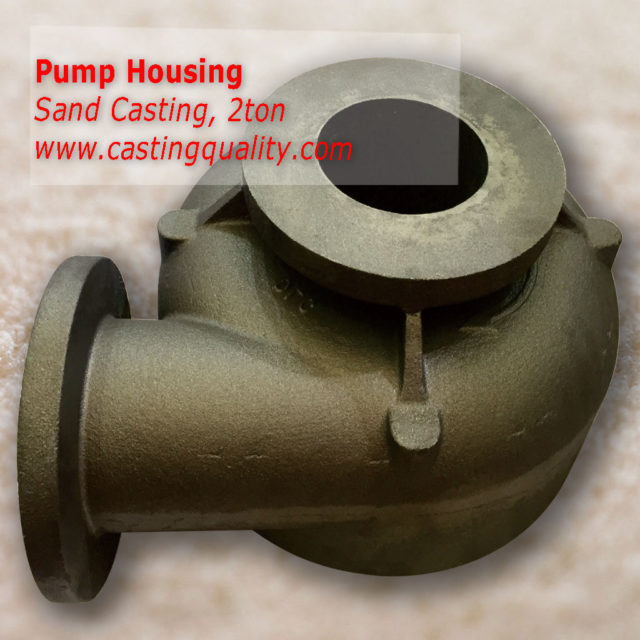

casting Material technology, such as ductile iron, carbon steel, gray iron, stainless steel, malleable iron and alloy.

brasion-Resistant Cast Iron ASTM A532 Class II type D Designation 20% Cr-Mo

Abrasion-Resistant Cast Iron ASTM A532 Class I type D Designation Ni-HICr

Abrasion-Resistant Cast Iron ASTM A532 Class III type A Designation 25% Cr

Abrasion-Resistant Cast Iron ASTM A532 Class I type B Designation Ni-Cr-LoC

Abrasion-Resistant Cast Iron ASTM A532 Class I type A Designation Ni-Cr-HIc

Abrasion-Resistant Cast Iron ASTM A532 Class I type C Designation Ni-Cr-GB

Abrasion-Resistant Cast Irons ASTM A532 Class II type B Designation 15% Cr-Mo

Stainless Steel GX40NiCrSiNb38-19 (EN 1.4849) in standard of EN 10295 and DIN 17465

Stainless steel GX40CrNiSi25-20 (EN 1.4848) in EN 10295 and DIN 17465

Leaded Red Brass C83450 in ASTM B30, ASTM B584 and ASTM B763 for casting purpose

Leaded Red Brass C83800 in ASTM B30, ASTM B271, ASTM B505, ASTM B584 and ASTM B763 for casting purpose

Cobalt Alloy UNS R30001, equivalent grade: Stellite 1, UNS W73031

Silicon Brass CuZn16Si4-C(CC761S), CuZn16Si4-B(CB761S) in EN 1982

Alloy Steel G17CrMo5-5 (EN 1.7357) in EN 10293 and EN 10213

Austempered Ductile Iron (ADI) in ASTM A897

Automotive Ductile (Nodular) Iron in SAE J434

Alloy Steel G20Mn5 (EN 1.6220) in casting standard of EN 10293, EN 10340 and EN 10213-3

Martensitic stainless steel GX4CrNi13-4 (EN 1.4317) in EN 10283.

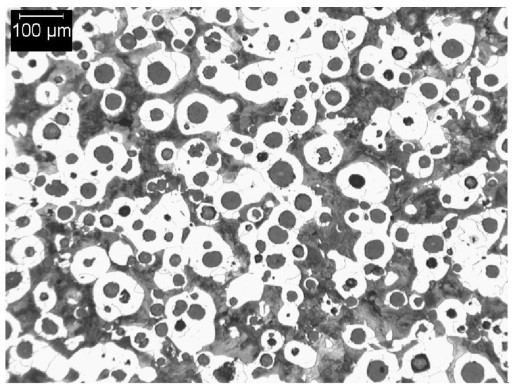

Austenitic Ductile Iron: A439 Type D-2 ,A439 Type D-2B ,A439 Type D-2C ,A439 Type D-3, A439 Type D-3A ,A439 Type D-4 ,A439 Type D-5 ,A439 Type D-5B, A439 Type D-5S